A dense suspension of particles in a fluid occurs in a variety of industrial applications such as inks, paints, foods, drilling fluids, cements, flow battery electrolytes and others. Understanding the flow behaviour of such suspensions is important in their transport and processing, and development of novel applications. We can use discrete element method (DEM) simulations of frictional spheres mediated by lubrication forces to capture some features of the rheology, such as shear thickening, of these suspensions [1, 2]. This work comprises several themes: a) how to extend current methodology to represent other rheological features of these materials, b) characterising materials using standard flows such as oscillatory flows, and shear reversal, and c) understanding flow under channels and in die extrusion. A brief description of these are given below.

- Shear thinning beyond shear thickening

- Recent experimental evidence shows that with increase in shear rates/stress, there are two shear thinning regimes separated by a shear thickening regime [3]. Using numerical simulations of lubricated particles, we aim to corroborate the experimental findings and hypotheses. We show that a decrease in particle friction coefficient at high loads can lead to a shear thinning region beyond shear thickening. •

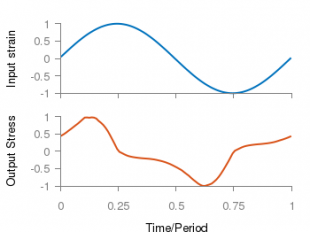

- Oscillatory shear flow and shear reversal

- Using DEM simulations, we find that the contribution of lubrication forces to shear thickening can be extracted by low amplitude oscillatory shear flow. These results are comparable to those obtained using shear reversal simulations. •

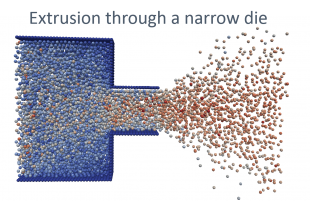

- Channel flow and die extrusion

- We are currently studying the efficacy of DEM simulations to accurately model flows of dense suspensions through narrow channels and extrusion through dies.

References

[1]R. Seto, R. Mari, J. F. Morris, and M. M. Denn. Discontinuous shear thickening of frictional hard-sphere suspensions. Phys. Rev. Lett., 111:218301, 2013.

[2]C. Ness and J. Sun. Flow regime transitions in dense non-brownian suspensions: Rheology, microstructural characterization, and constitutive modeling. Phys. Rev. E, 91:012201, 2015.

[3]G. Chatté, J. Comtet, A. Niguès, L. Bocquet, A. Siria, G. Ducouret, F. Lequeux, N. Lenoir, G. Ovarlez, and A. Colin. Shear thinning in non-Brownian suspensions. Soft Matter, 14:879–893, 2018.