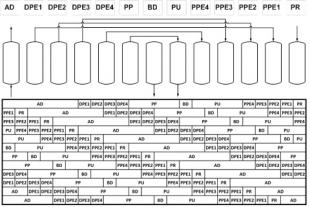

- Optimising a 12-column H2 PSA process for achieving 93+% H2 recovery at 99.99+ % H2 purity when integrated with a carbon capture unit

- Developing a patented process technology of linking a carbon capture unit with the H2 PSA unit to improve the overall process economics by reducing the energy consumption for carbon capture

- Constructing a lab-scale 6-column Pressure Swing Adsorption (PSA) for demonstrating the prediction by process simulators

Further Information:

M. Luberti, D. Friedrich, S. Brandani, H. Ahn*, Design of a H2 PSA for cogeneration of ultrapure hydrogen and power at an advanced integrated gasification combined cycle with pre-combustion capture. Adsorption, 20(2014), 511-524. http://link.springer.com/article/10.1007/s10450-013-9598-0

Principal Investigator:

Co-Investigators:

Postgraduate Researchers:

Last modified:

Thursday, May 13, 2021 - 17:49