This project is a collaboration between the University of Edinburgh and AkzoNobel’s Marine, Protective & Yacht Coatings, the world leader in marine coatings, and will include a three-month secondment at AkzoNobel.

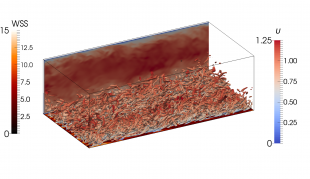

The challenge of predicting the resistance of ship hulls in real sailing conditions is due to the wide range of length-scales involved, from the micron-scale of the coating roughness to the metre-scale of the ship's boundary layer thickness (Raupach et al. Appl. Mech. Rev. 44 1991, Gad-el-Hak Appl. Mech. Rev. 49 1996). The width of this range of scales, and the fluid mechanics interaction between the scales, make the physics impossible to be replicated exactly in a laboratory setting (Gad-el-Hak Prog. Aerosp. Sci. 38 2002, Jimenez Annu. Rev. Fluid Mech. 36 2004).

Recent work funded by AkzoNobel's Marine, Protective & Yacht Coatings and undertaken at the University of Edinburgh showed the strong interaction between roughness features of different sizes. However, current practice is to consider a single equivalent roughness height to model the effect of roughness on ship hulls (Yeginbayeva et al. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 233 2019). How to model the non-uniform distributions of roughness and combination of micro and macro roughnesses in numerical simulations of ship hulls is currently unknown (Chung et al, Annu. Rev. Fluid Mech. 53 2021; Andersson et al, Appl. Ocean Res. 99 2020). This project aims to address this key industry challenge with fundamental fluid mechanics research.

The aim of this project is to develop a methodology to accurately predict the friction resistance of ship hulls at full scale accounting for heterogenous fouling roughness, including hard fouling such as barnacles, and patchy slime with different thickness. New theoretical models of the interaction between different roughness features will be developed. These will be implemented into a Navier-Stokes code (using the OpenFOAM tool) to compute the friction resistance of a full-scale hull for different surface conditions.

NOTES ON APPLYING

Please check additional instructions on https://voilab.eng.ed.ac.uk/phd

Further Information:

For more information on the research environment, see the website of the research group of the main supervisor, Prof. Ignazio Maria Viola: www.voilab.eng.ed.ac.uk

For more information on the industrial partner, see https://www.akzonobel.com/en/about-us/our-businesses/marine-protective-a...

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

Closing Date:

Principal Supervisor:

Eligibility:

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree.

Applicants must have studied fluid mechanics in their undergraduate courses, and must demonstrate knowledge of the fundamentals of turbulent flow. Expertise in computational fluid dynamics and experience in OpenFOAM is desirable but not essential.

Further information on English language requirements for EU/Overseas applicants.

Funding:

Funding is open to all applicants, but funding for Overseas students is limited, due to the funder’s eligibility rules.

Applications are also welcomed from candidates who are able to self-fund their studies, or who have secured a scholarship or similar.