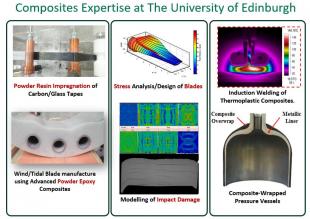

The Composites Group at The University of Edinburgh was founded in 2015, and has 7 academic and ca. 30 research staff & students (May 2021). Its focus is primarily on fibre reinforced polymer composite materials. Fibres studied include carbon, glass, basalt and natural fibres. Resins studied include both thermosets (e.g. epoxies, vinyl/poly esters) and thermoplastics (e.g. PEEK, PEK, Nylon-6).

Main Research Interests

- Powder epoxy resins for thick section composite processing (e.g. wind blade root sections, shipping hulls).

- Reaction Injection Moulding of PA6 (Nylon) Glass/Carbon Reinforced Composites.

- Automated Carbon Tape Production Line producing powder-epoxy impregnated towpreg for Automated Tape Placement

- Fibre-Metal Laminates for improved ductility and toughness.

- Design and Testing of Large Composite Structures (e.g. Powderblade and Fastblade projects).

- Biomimetic Composites.

- Numerical Stress Modelling (Abaqus & Python)

Composites Materials Manufacturing and Testing Laboratories

The group has a total laboratory space of 210 square metres, with separate Composites Processing and Composites Testing facilities.

Composites Processing Equipment:

• Heated vacuum tooling and accessories

• Fume hoods and tool preparation areas

• Thermoplastic composites press system

• Reaction moulding system, mixing and dosing system for liquid thermosets and thermoplastics

• Trimming and specimen extraction facilities

Composites Testing Equipment:

• 250kN Zwick static test machine with hydraulic grips

• 100kN and 250kN servo-hydraulic test machines

• Humidity conditioning chamber

• Fluid immersion baths for specimen conditioning

• End-tab bonding press

• Extensometers

• Dynamic Mechanical Thermal Analysis (DMTA)

• Differential Scanning Calorimetry (DSC)

• Optical microscopes and specimen preparation facilities

• Scanning Electron Microscopy