Summary

The project tackles challenges in experimental and theoretical development of low carbon concrete technology via innovations that augment the use of industry wastes as cement replacement and with emphasis on the use of biochar to realise carbon capture and storage capability.

Project background

Concrete is the most widely used man-made material in existence. Its production mostly relies on the heavy exploitation of natural resources including limestone, granite and water. The production of its key ingredient - cement - is energy-intensive, which accounts for 8% of global CO2 emissions, besides being identified as the root of various other social and environmental problems. This project will explore effective ways of utilising low-carbon alternatives as binders for concrete to help alleviate cement production and its usage, contributing to the achievement of a net-zero built environment. Key highlights include the synthesis of cementitious binder that capitalises on suitable proportioning of recyclable waste materials to meet the required engineering requirements, whilst enabling significant reduction of carbon footprint by avoiding the use of virgin materials. The mixture to be developed will also be functionalised for achieving active and passive CO2 adsorption and storage. The success of this project relies on robust and coherent laboratory investigations, theoretical studies, and if necessary numerical modelling to appraise and quantify the performance criteria of cementitious mixtures, focusing on variations in material proportions and production methods. Materials that are of interest include biochar derived from different sources, pulverised fuel ash, slag and bottom ash. Flexibility in the Candidate’s interest, experience and motivation will influence the consolidation of project scope and planning for activities involved.

Research questions

- Can we produce cement with locally sourced waste materials?

- How do we effectively reduce the carbon footprint of concrete construction, from the material preparation and utilisation perspectives?

- Can we achieve carbon adsorption and storage in concrete structures without trade-off in their strength and serviceability performance?

- How do we develop a rational mixture design and preparation methodology that ensures the fulfilment of standard construction requirements?

- Will the development help realise disruptive carbon neutral/ negative technology for the concrete industry?

Methodology

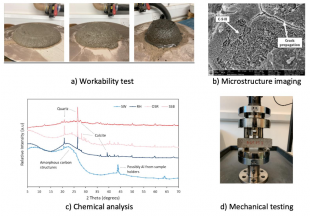

Material Characterisation:

Investigations will be carried out on the physical and chemical properties of individual constituent materials (Portland cement, biochar, industry slags and ashes etc) and the synthesised cementitious mixtures. Work is first focused on quantifying the physical characteristics of the constituent materials such as particle size distribution, fineness, porosity and toughness. Then studies will be carried out to analyse the mixtures prepared with structured variations in material proportions, emphasising chemical reactions and hydration kinetics, as well as the synthesised chemical compound and micro-structure evolvement. These data are critical to formulating a systematic understanding of parameters that influence the properties of the mixture at the physical and chemical levels.

Design and Test:

Mixture design will be carried out based on the findings of the “Material Characterisation” work package. Laboratory samples will be prepared and tested for fresh, mechanical and durability properties. These may include slump/flow, compression, tensile, water absorption, porosity, permeability, carbonation, corrosion resistance and fire resistance. The effect of the sample curing method on their performance will also be studied to complement the understanding and identification of optimum material compositions that could be further developed for structural or non-structural uses. Whenever appropriate the project will engage in developing larger scale concrete members to be mechanically loaded and evaluated to better understand the efficiency of the developed mixtures for structural use.

Carbon capture and storage (CCS):

Mixtures will be mineralised and functionalised for active carbon capture. A bespoke CO2 pressure chamber will be developed to study the capability of the fresh and hardened mixtures in achieving carbon adsorption and curing for improved properties. The effect of CO2 on mixture performance, in particular strength and durability will be assessed to identify governing factors associated with realising active carbon storage in mixtures with different combinations of waste materials.

Carbon accounting:

Analysis of carbon accounting for the developed mixtures will be carried out. Development or adaptation of a suitable life cycle cost analysis tool might be required for this purpose. The outcome of this analysis will enable enhanced knowledge of quantitatively evaluating the effect of reducing carbon footprint through implementing different approaches of waste material incorporation in concrete.

Engagement and Result Dissemination:

Engagement activities with industry and the public will be organised with research partners at specific interims, in seminars and workshops to communicate research findings and raise awareness of the importance of mitigating carbon footprint in concrete construction. Findings of research will also be disseminated via conference presentations and journal article publications to reach out to the wider research community and potentially industry stakeholders.

| Work Package | Year 1 | Year 2 | Year 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | Q1 | Q2 | Q3 | Q4 | Q1 | Q2 | Q3 | Q4 | |

| Material Characterisation | X | X | X | x | x | x | x | x | ||||

| Design and Test | x | x | x | x | x | x | x | x | ||||

| CCS | x | x | x | x | x | x | ||||||

| Carbon Accounting | x | x | x | x | ||||||||

| Engagement and Results Dissemination | x | x | x | |||||||||

Training

A comprehensive training programme will be provided comprising both specialist scientific training and generic transferable and professional skills. This will include training of the use of material characterisation equipment e.g. scanning electron microscopy, X-Ray diffraction, thermogravimetric analyser, universal testing machine, and physical measurement instrument such as displacement transducer, digital image correlation. Training will be provided on the use of numerical software based on discreet element modelling and analysis.

Requirements

Student should have a solid background in civil and structural engineering with preferred knowledge in cementitious material science. Ideally, student would have already developed some skills and experience in material characterisation, mortar/ concrete mixture design, preparation and testing. Basic knowledge of numerical modelling, carbon accounting and life-cycle cost analysis will also be desired.

References

Andrew, R.M. Global CO2 emissions from cement production, 1928–2017, Earth System Science Data, 2018, 10, 2213–2239.

Praneeth, S.; Guo, R.; Wang, T.; Dubey, B.K.; Sarmah, A.K. Accelerated Carbonation of Biochar Reinforced Cement-Fly Ash Composites: Enhancing And Sequestering CO2 in Building Materials, Construction and Building Materials,

Winters, D.; Boakye, K.; Simske S. Toward Carbon-Neutral Concrete through Biochar-Cement-Calcium Carbonate Composites: A critical Review, Sustainability, 2022, 14: 4633.

Ravikumar, D.; Zhang, D.; Keoleian, G.; Miller, S.; Sick, V.; Li V. Carbon Dioxide Utilization in Concrete Curing Might Not Produce a Net Climate Benefit. Nature Communications, 2021, 12:855.

Roberts, K.G.; Gloy, B.A.; Joseph, S.; Scott, N.R.; Lehmann, J. Life Cycle Assessment of Biochar Systems: Estimating the Energetic, Economic, and Climate Change Potential, Environmental Science and Technology, 2010, 44, 2:827–833.

Ashraf, W. Carbonation of cement-based materials: challenges and opportunities, Construction and Building Materials, 2016, 120: 558–570.

Apply by Thu Jan 04 2024 at 12:00

Further Information:

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

Closing Date:

Principal Supervisor:

Assistant Supervisor:

Eligibility:

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

Funding:

Tuition fees + stipend are available for Home/EU and International students.